The American Competitiveness Institute (ACI) hosted a Lead-Free Soldering Summit on July 13–14 at its facilities in Philadelphia, Pennsylvania. This pivotal event focused on the specialized needs of the military and aerospace electronics sectors, drawing participation from representatives of the Army, Navy, Air Force, NASA, government agencies, industry leaders, and academia. Attendees shared valuable technical insights and programmatic strategies through dedicated presentations.

The Military and Aerospace Perspective

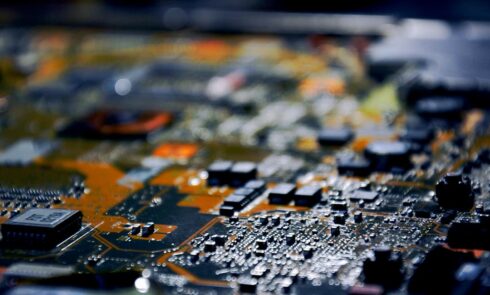

Although the WEEE (Waste Electrical and Electronic Equipment) and RoHS (Restriction of Hazardous Substances) directives formally exempt military and aerospace electronics, the transition to lead-free technologies in commercial markets poses a significant challenge. With military and aerospace electronics comprising less than 1% of the global market, the shift in commercial supply chains to lead-free solders is expected to have a ripple effect, forcing these sectors to adapt.

Implications of Lead-Free Soldering

The transition to lead-free soldering extends beyond simple manufacturing changes. It impacts:

- Hardware Reliability: Ensuring solder joints withstand extreme environments.

- Rework and Repair Processes: Modifying existing procedures to accommodate lead-free technologies.

- Program Sustainment: Adapting long-term support strategies for legacy systems.

- Configuration Management: Ensuring compatibility between leaded and lead-free components.

- Supply Chain Dynamics: Navigating shifts in material availability.

- COTS Integration: Managing the impact of lead-free standards on commercial-off-the-shelf (COTS) components, especially in light of Defense Acquisition Reform initiatives.

Summit Goals

The summit aimed to:

- Assess Current Knowledge: Catalog existing lead-free soldering activities and plans within the military and aerospace sectors.

- Identify Knowledge Gaps: Highlight areas requiring further investigation to facilitate the transition.

- Develop a Transition Strategy: Outline a clear roadmap for implementing lead-free soldering within the unique framework of military and aerospace electronics.

Key Outcomes

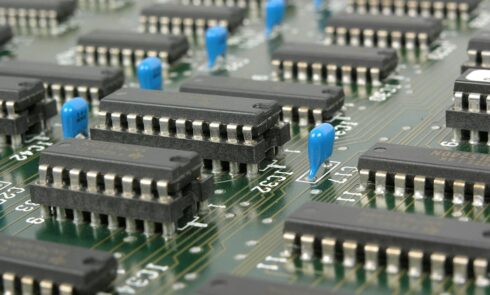

Participants identified several technical and programmatic challenges specific to military and aerospace applications, including:

- Thermal and mechanical stress resilience of lead-free solder joints.

- Long-term reliability in harsh environments.

- Effective rework and repair techniques for high-reliability systems.

- Supply chain adaptations to accommodate new materials.

The summit emphasized the importance of applied research and development to address these challenges. Discussions also highlighted the need for collaboration across sectors to develop solutions tailored to high-reliability applications.

Looking Ahead

The attendees agreed on the necessity of a follow-up summit to monitor progress and share updates on advancements in lead-free soldering for military and aerospace electronics. This future event will continue the dialogue, ensuring the development of reliable, compliant, and sustainable solutions for these critical sectors.

The Lead-Free Soldering Summit demonstrated ACI’s commitment to supporting the military and aerospace community in navigating the complexities of lead-free transition while maintaining the highest standards of reliability and performance.