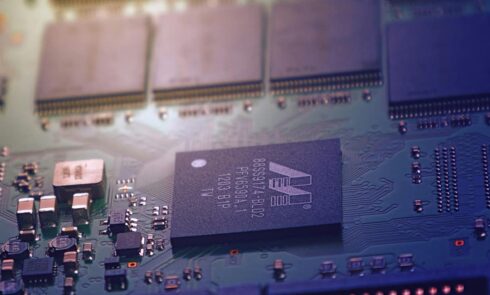

Artificial intelligence (AI) is revolutionizing industries across the globe, and electronics manufacturing is no exception. As the demand for smarter, more efficient production processes increases, AI is playing a key role in transforming the way electronic devices are designed, produced, and maintained. From optimizing manufacturing lines to enhancing quality control, AI is reshaping every aspect of electronics production.

AI in Electronics Design and Development

The role of AI in electronics manufacturing begins at the design stage. Traditionally, designing electronic circuits and systems has been a highly complex process that requires extensive testing, analysis, and optimization. With AI, engineers can now leverage advanced algorithms to automate and optimize the design process. Machine learning models can predict the performance of components, simulate potential failures, and help in selecting the best materials for specific applications. This accelerates the development of new products and reduces the time required for testing and revisions.

For instance, AI-powered tools can analyze vast amounts of data from past designs and manufacturing processes to suggest improvements, predict potential faults, and even generate novel design solutions. This significantly shortens the time from concept to prototype, enabling faster innovation in the electronics sector.

Smart Manufacturing and Automation

In the production phase, AI is making a substantial impact by improving manufacturing efficiency. Through AI-driven automation, machines and robots can now perform tasks with high precision, such as assembling components, soldering, and testing. Smart factories, powered by AI, are capable of continuously monitoring and adjusting production processes to ensure optimal performance and minimize waste.

For example, AI algorithms can analyze data from sensors and cameras installed on assembly lines to detect defects in real time. This allows manufacturers to identify issues as they occur, reducing the need for manual inspection and improving the overall quality of the products. Additionally, AI systems can optimize production schedules by predicting demand, reducing downtime, and ensuring that resources are used efficiently.

AI for Predictive Maintenance

One of the most significant benefits AI brings to electronics manufacturing is the ability to predict and prevent equipment failures before they occur. Traditional maintenance strategies often rely on fixed schedules or reactive measures, meaning equipment is either serviced too early or too late. AI-powered predictive maintenance, on the other hand, uses machine learning algorithms to analyze historical data from machinery and predict when a part is likely to fail.

This helps manufacturers avoid unplanned downtime, increase equipment lifespan, and lower maintenance costs. Sensors and AI systems can continuously monitor machinery health and performance, sending alerts when a part requires attention. This ensures that production lines remain operational and efficient, avoiding costly delays and disruptions.

AI-Enhanced Quality Control

Ensuring high-quality standards in electronics manufacturing is crucial. AI is transforming traditional quality control methods by automating inspection processes with greater accuracy. Computer vision systems powered by AI can now inspect circuit boards and components for defects such as incorrect solder joints, missing parts, or damage. These systems can detect even the smallest irregularities that might be overlooked by human inspectors.

Additionally, AI can optimize testing procedures by analyzing vast datasets from tests on finished products. This allows manufacturers to identify patterns and trends that would be difficult for humans to discern, leading to improved defect detection, better decision-making, and higher overall product quality.

AI and Supply Chain Management

AI is also playing a pivotal role in streamlining supply chains in electronics manufacturing. Managing inventory, sourcing materials, and predicting demand can be complex, but AI systems can help optimize these processes. By analyzing past sales data, market trends, and external factors such as geopolitical events or natural disasters, AI can forecast demand more accurately and help manufacturers plan production schedules accordingly.

AI also helps in optimizing inventory management by tracking stock levels, predicting shortages, and automating ordering processes. This reduces the risk of overstocking or running out of critical materials, ensuring a smooth and efficient production process.

The Future of AI in Electronics Manufacturing

As AI continues to advance, its role in electronics manufacturing will only grow. We can expect even more intelligent systems that can autonomously manage entire production lines, predict and adapt to changing market conditions, and optimize energy consumption. AI could lead to the creation of fully autonomous factories where human intervention is minimal, and the production process is continuously self-improving.

Moreover, AI will facilitate more sustainable manufacturing practices. By reducing waste, improving energy efficiency, and enabling better resource management, AI can help electronics manufacturers achieve their sustainability goals while maintaining high standards of performance and innovation.

Artificial intelligence is fundamentally changing electronics manufacturing by driving innovation, improving efficiency, enhancing product quality, and reducing costs. From design and development to production, testing, and supply chain management, AI is helping manufacturers adapt to the challenges of an increasingly competitive and fast-paced market. As AI technology continues to evolve, its impact on the electronics industry will be profound, creating smarter, more efficient, and more sustainable manufacturing processes for the future.